Contact Supplier

Mr. Jeff

Leave a messageBasic Info

Model NO.: Vmc855

Application: Metal

Process Usage: Metal-Cutting CNC Machine Tools, CNC Non-Conventional Machine Tools, Metal-Forming CNC Machine Tools

Movement Method: Linear Control

Control Method: Closed-Loop Control

Numerical Control: CNC/MNC

Processing Precision: 0.04~0.05(mm)

Performance Classification: High-End CNC Machine Tools

Certification: Ce

Condition: New

Transport Package: Packing in Seaworthy Wooden Cases

Specification: Dimension(L*W*H): 2800*2360*2450mm

Trademark: DRC

Origin: China

Production Capacity: 500

Customization: Available

After-sales Service: 1

Warranty: 1 Year

Shipping Cost: Contact the supplier about freight and estimated delivery time.

Additional Info

Supply Ability: 500

Product Description

| Model NO. | Vmc855 |

|---|---|

| Application | Metal |

| Process Usage | Metal-Cutting CNC machine tools, CNC Non-Conventional Machine Tools, Metal-Forming CNC Machine Tools |

| Movement Method | Linear Control |

| Control Method | Closed-Loop Control |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.04~0.05(mm) |

| Performance Classification | High-End CNC Machine Tools |

| Certification | CE |

| Condition | New |

| Transport Package | Packing in Seaworthy Wooden Cases |

| Specification | Dimension(L*W*H): 2800*2360*2450mm |

| Trademark | DRC |

| Origin | China |

| Production Capacity | 500 |

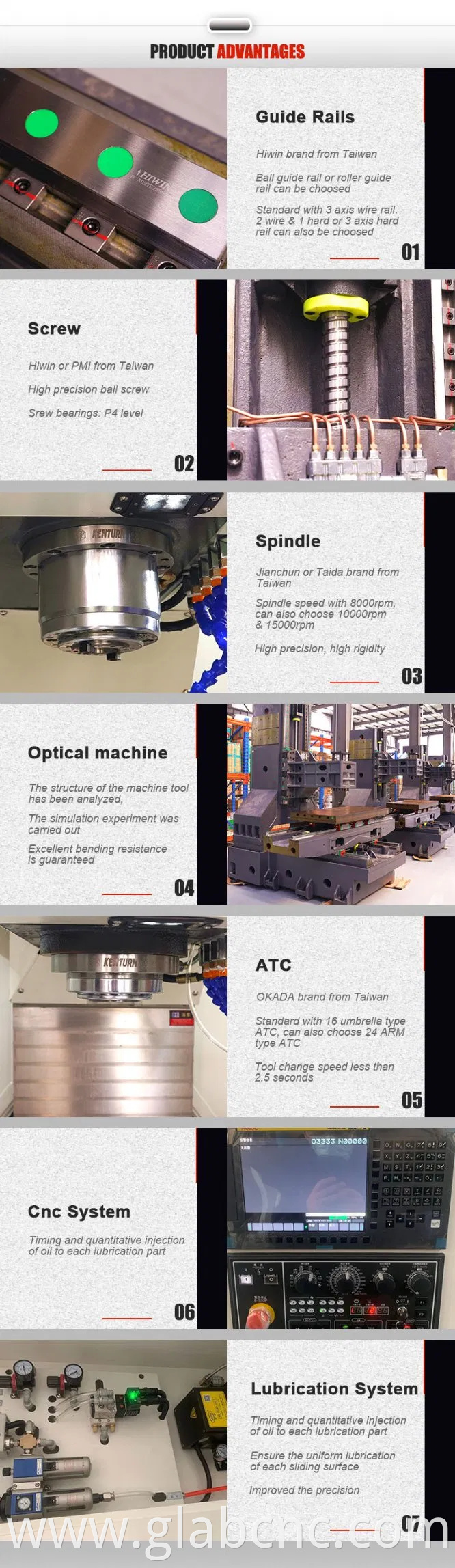

Casting: HT300 resin sand wear-resistant castings have high density and good wear resistance! The saddle adopts a double-layer casting structure, and the large A-shaped column structure shows high rigidity cutting ability.

Spindle: Standard is high speed BT40-150 belt driven Taiwan spindle---8000RPM; Optional is 10000/12000/15000 rpm .simple and compact structure, high efficiency, low noise, low vibration , high precision,and good surface finishing.

| X /Y/Z axis travel | 800/500/500mm | 1050/500/500mm |

|---|---|---|

| Spindle nose to table surface | 120-620mm | 120-620mm |

| X/Y/Z axis AC servo motor | torque N.m 15/15/22 | torque N.m 15/15/22 |

| Spindle center to column surface | 550mm | 550mm |

| Worktable | ||

| table size | 1000×550mm | 1000×550mm |

| Max.loading | 600kg | 600kg |

| T Shot | 5×18×90mm | 5×18×90mm |

| Feeding parameters | ||

| X/Y/Z axis rapid feed | 24/24/20m/min | 20/20/18m/min |

| Cutting feed | 1-10m/min | 1-10m/min |

| Spindle parameters | ||

| Main shaft connection | Belt | Belt |

| Spindle taper | BT40-140 | BT40-150 |

| Range of spindle speed | 8000rpm | 8000rpm |

| Spindle motor | 7.5kW | 7.5kW |

| ATC paremeters | ||

| ATC capacity | 24qty | 24qty |

| Max.tool dia | Φ80/Φ150mm | Φ80/Φ150mm |

| Max.tool weight | 8kg | 8kg |

| Precision | ||

| Position accuracy(JIS standard) | ±0.008/300mm | ±0.008/300mm |

| Repeat positioning accuracy(JIS standard) | ±0.005mm | ±0.005mm |

| Shape and weight | ||

| Dimensions | 2750×2300×2300mm | 2800×2360×2450mm |

| Weight | 5200kg | 5600kg |

Screw: Standard is hardened guide way,optional is Taiwan Hiwin linear guide way.The guide screw adopts the imported JIS-C3 grinding grade pre-stretched nut screw to eliminate the backlash, after heat treatment, it has good rigidity, wear resistance, and guarantees the high precision of the operation.

Auto tool changer: Taiwan hat type (16 knives) tool magazine. Advantages: low wear, long life, easy adjustment, and low failure rate.Optional configuration is Taiwan 20/24 disc type Auto tool changer.

Controller system Controller system: there is GSK /KND/SIEMENS/SYNTEC/FANUC controller system could to be choosed Optional configuraton:4th and 5th axis : 4th and 5th axis can be choosed as opintional,Horizontal & vertical cnc rotary table can be choose as optional. Especially for special jobs.High precision, improve processing efficiency, and shorten the processing flow.

PROBE MEASURING METROL , RENISHAW or PIONEER brand workpiece measuring system and tool measuring system are optional configurations.

Chip conveyor outside machine The machine tool chip conveyor is mainly used to collect various metal and non-metal scraps produced by the machine and transfer the scraps to the collection vehicle. It can be used in conjunction with the filter water tank to recycle various coolants.

24 tools arm type Auto tool changer The tool change speed is fast, within 4s. The mechanical arm pulls the tool from the tool magazine and the spindle at the same time and installs it on the spindle and the tool magazine after a 180° rotation to complete the tool change process.

Product Categories : CNC Machining Center > Vertical Machining Center

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.